The medical device industry plays a pivotal role in advancing healthcare across the

globe. With products developed and manufactured in one region often being marketed

and sold internationally, it is crucial for medical device companies to understand the

complex web of regulations that govern these products in different parts of the world.

Ensuring that medical devices are safe and effective for patients is paramount. As a

result, medical devices are subject to stringent regulations by various regional

regulatory bodies. In this post, I’ll provide a snapshot of the several regulatory bodies

and requirements.

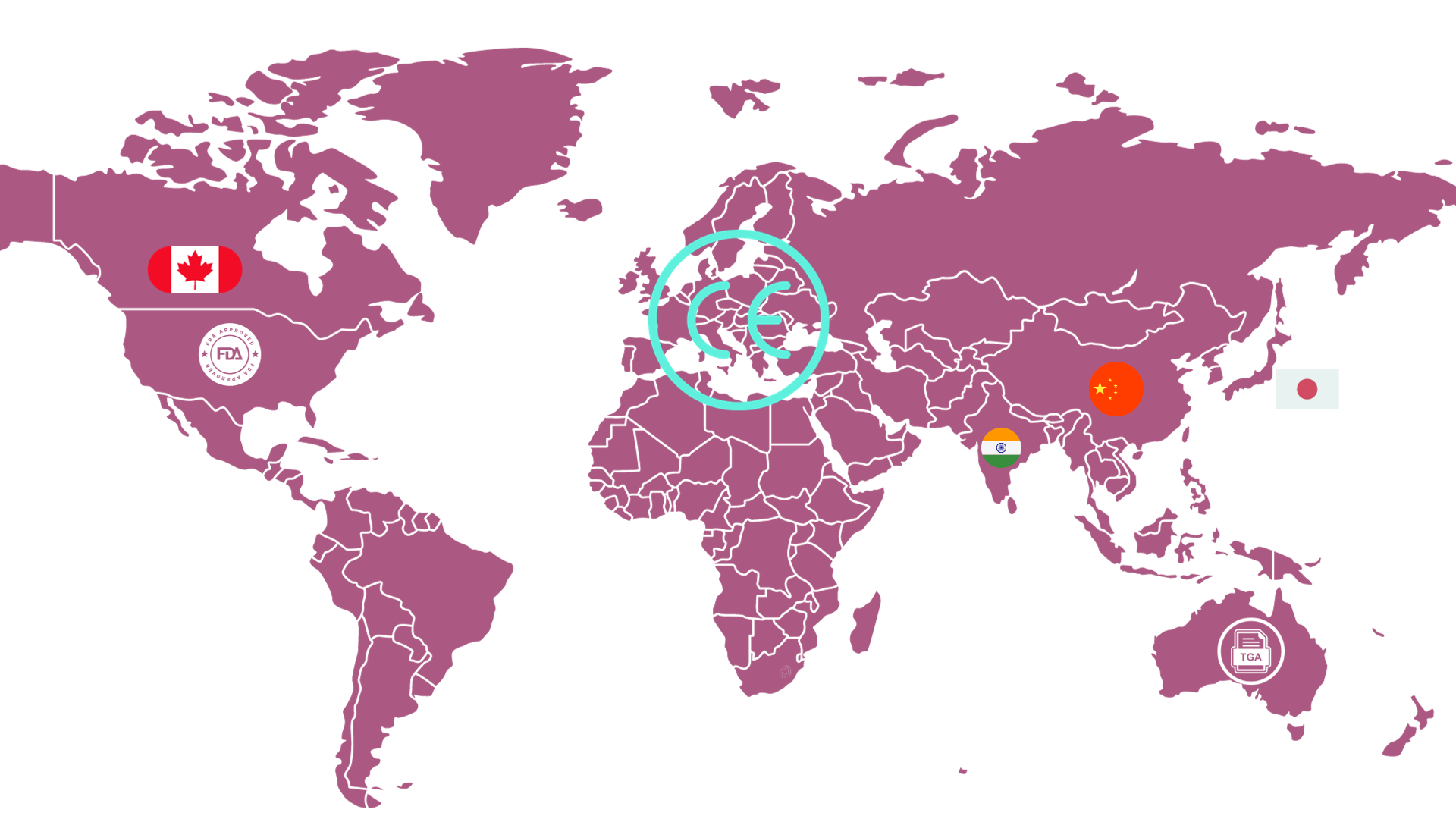

The following are some of the key regulatory bodies for medical devices in different

regions:

• United States: Food and Drug Administration (FDA).

• European Union: European Commission (EC).

• Canada: Health Canada (HC).

• Japan: Pharmaceutical and Medical Devices Agency (PMDA).

• Australia: Therapeutic Goods Administration (TGA).

• China: National Medical Products Administration (NMPA).

• India: Central Drugs Standard Control Organization (CDSCO).

Regulatory requirements

The specific regulatory requirements for medical devices vary depending on the type of

device and the region where it is being marketed. However, some general requirements

apply to all medical devices, such as:

• The device must be safe and effective for its intended use.

• The device must be manufactured in accordance with quality system regulations.

• The device must be labeled accurately and informatively.

• The manufacturer must report any adverse events associated with the device to

the regulatory authority.

Premarket approval

Some medical devices require premarket approval from the regulatory authority before

being marketed. This is typically required for high-risk devices, such as implants and life-sustaining devices.

To obtain premarket approval, the manufacturer must submit a premarket approval

application to the regulatory authority. The application must include technical and

clinical data that demonstrate the safety, performance, and efficacy of the device.

Postmarket surveillance

Once a medical device is marketed, the manufacturer must monitor its safety,

performance, and efficacy. This is known as postmarket surveillance.

The manufacturer must collect and analyze data from postmarket surveillance activities,

such as adverse event reports and customer complaints. This data can be used to

identify and address any safety, performance, or efficacy concerns with the device.

Regulatory requirements in different regions

The following is a brief overview of the regulatory requirements for medical devices in

different regions:

1. USA – Food and Drug Administration (FDA)

• Regulatory Body: The primary body overseeing medical device regulations in

the USA is the Food and Drug Administration (FDA). The FDA regulates

medical devices under the Medical Device Amendments of 1976.

• Classification System: The FDA classifies medical devices into three

categories based on risk: Class I (low risk), Class II (moderate risk), and Class

III (high risk).

• Pre-Market Approval (PMA): For high-risk devices (Class III), manufacturers

typically need to obtain a PMA, which requires rigorous clinical testing and

review.

• 510(k) Clearance: For most Class II and some Class I devices, manufacturers

can seek 510(k) clearance, demonstrating that the device is substantially

equivalent to a device already on the market.

• De Novo request: Provides a marketing pathway to classify novel medical

devices that are usually low risk and provide reproducible controls to manage

those risks,

• Humanitarian Device Exemption (HDE): A marketing application exempt

from effectiveness requirements that is subject to certain profit and use

restrictions.

• Establishment Registration: All facilities producing and distributing devices

must be registered annually with the FDA.

• Quality System Regulation (QSR): Manufacturers must establish and adhere

to quality systems to ensure their products consistently meet regulatory

requirements.

2. EU – CE Marking

• Regulatory Body: In the European Union, the regulatory framework revolves

around obtaining a CE Mark.

• Medical Device Regulations (MDR and IVDR): The EU’s Regulations provide a

modernized and more robust EU legislative framework, ensuring better

protection of public health and patient safety.

• Classification System: Devices are classified into four classes – Class I, IIa, IIb,

and III, ascending in risk.

• Notified Bodies: Unlike the centralized FDA system, the EU relies on Notified

Bodies – independent entities designated by EU countries to assess the

conformity of certain products before being placed on the market.

• Conformity Assessment: Before affixing the CE marking, manufacturers must

undertake a conformity assessment, demonstrating that the device meets all

regulatory requirements.

• Quality management systems (QMS): Must meet ISO 13485.

3. Canada: Health Canada

• Regulatory Body: Health Canada Medical Devices Bureau (MDB) regulates

medical devices in Canada under the Medical Devices Regulations (MDR).

• Classification System: Health Canada classifies medical devices into four risk

categories: Class I (low risk), Class II (medium risk), Class III (high risk), and

Class IV (implantable).

• Conformity Assessment: Class III and Class IV devices require premarket

approval.

4. Japan: PMDA

• Regulatory Body: The PMDA, in collaboration with the Ministry of Health,

Labor, and Welfare (MHLW), manages the country’s medical device

regulations.

• Device Classification: Devices are classified into Classes I to IV based on risk,

with IV being the highest.

• Pre-market Certification/Approval: Depending on the device class, either

certification (by registered certification bodies) or approval (by the MHLW) is

needed. Extensive technical documentation and clinical data must be

submitted to PMDA for review.

• Quality Management System (QMS) Audit: Manufacturing quality control

and design/development management systems must comply with Japanese

regulations based on ISO 13485 and ISO 14971. Labeling must include

indications for use in Japanese. Post-market surveillance is also mandated.

5. Australia – Therapeutic Goods Administration (TGA)

• Regulatory Body: The TGA oversees the safety, effectiveness, and quality of

therapeutic goods, including medical devices.

• Australian Register of Therapeutic Goods (ARTG): Before a device can be

legally supplied in Australia, it must be included in the ARTG.

• Classification System: Medical devices are classified based on risk, ranging

from Class I (lowest risk) to Class III (highest risk). There’s also a separate

category for active implantable medical devices.

• Conformity Assessment: Similar to the EU, Australian manufacturers must

undergo a conformity assessment. The specifics vary depending on the

device’s classification and origin.

• Post-market monitoring: The TGA actively monitors the performance of

devices on the market, ensuring that they continue to meet safety and

performance criteria.

6. China – NMPA

• Regulatory Body: National Medical Products Administration (NMPA),

formerly the China FDA, the NMPA is responsible for supervising the safety

management of food, drugs, and medical devices.

• Device Classification: Devices are classified into Class I, II, or III based on risk.

Class III devices are the highest risk.

• Registration and Approval: All devices, regardless of classification, require

NMPA registration and approval.

• Clinical Trials: Local clinical trials and technical documentation translations

are often needed, especially for higher-risk devices.

7. India – CDSCO

• Regulatory Body: The Central Drugs Standard Control Organization (CDSCO)

is India’s primary authority for drug and device regulation. The CDSCO

regulates medical devices in India under the Drugs and Cosmetics Act.

• Device Classification: The CDSCO classifies medical devices into four risk

categories: Class A (low risk), Class B (moderate risk), Class C (high risk), and

Class D (implantable). Class C and Class D devices require premarket

approval.

• Device Registration and Licensing: Before market introduction, devices must

be registered with CDSCO, and manufacturers need licenses.

• Clinical Trials: Clinical evidence might be required depending on the device

classification.

• Import License: An additional import license is essential for foreign

manufacturers.

Conclusion

Medical device regulations are in place to protect patients from unsafe and ineffective

medical devices. These regulations vary from country to country, but they all share the

same goal: to ensure that medical devices are safe and effective for their intended use.

While this post offers a brief overview, regulatory affairs professionals are the “real

heroes” navigating these intricate frameworks, ensuring that innovations in healthcare meet the highest standards of safety and efficacy.